Science Project to Mainstream Automation

Universal Robots shipped the world’s first commercially viable collaborative robot in 2008, three years after being founded in Odense, Denmark. The early years of UR’s cobot market were dominated by machine tending, assembly, packaging and palletizing – all applications that relied on the accurate picking and placing of parts and boxes. However, arc welding is a different type of application, far more demanding than the typical machine tending project.

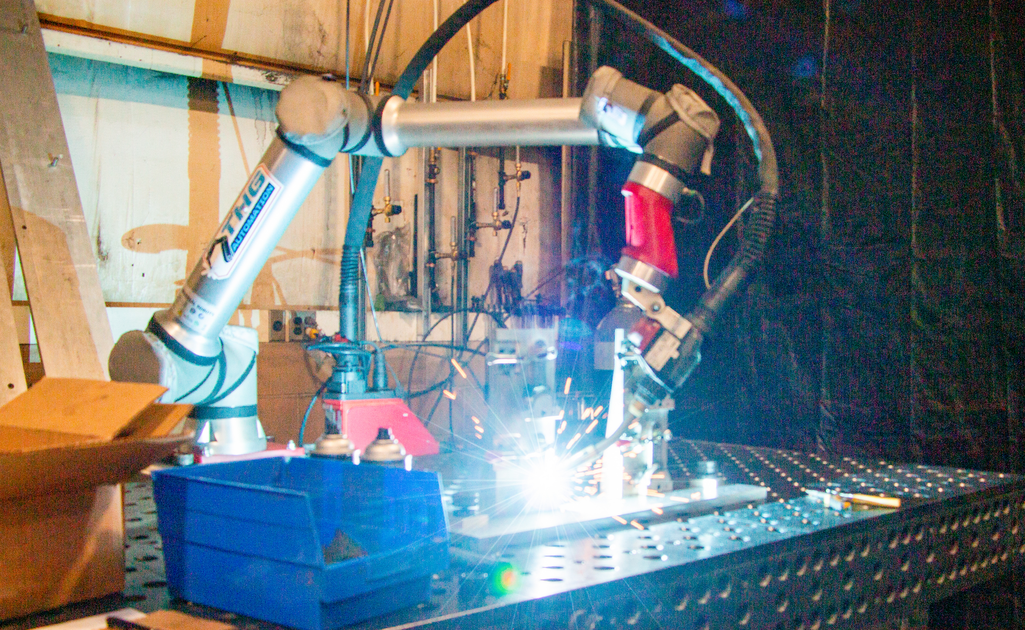

It took nine long years for the first UR cobot based arc welding system to hit the market in 2017, and that transition accelerated in 2018 with the introduction of the e-Series family of controllers and related versions of PolyScope, the UR operating system and programming & development environment. This combination supported the precise path following performance, tool tip attitude & speed control and advanced process controls that welding applications required.

Cobot welders brought immediate benefits versus traditional robot welders to fab shops of all sizes. Automation investments to boost productivity are not new – arc welding robots have been on the market since the late 1970’s.